Manufacturer & Exporter of Bulk Bags and Fabrics

We, Ace Packaging, are engaged in manufacturing, exporting and supplying FIBC (Flexible Intermediate Bulk container), PP bags and HDPE bags. Our bags are a Polypropylene based ready to use industrial container capable of carrying product loads ranging from 50 kgs to 2000 kgs. These bags are flexible, easy to store, fill, stock and discharge.

FIBC Bags

Flexible intermediate bulk container also known as jumbo bag is an industrial container made of flexible fabric that is designed for storing and transporting dry, flow able products, such as sand, fertilizer, and granules of plastic etc. These bags are made of thick woven strands of polypropylene which can be either coated or uncoated. The capacity of bags is normally between 1000kgs – 1500kgs.

Transporting and loading process is either done through pallets or by lifting it from the loops. Bags can be customized as per customer’s requirements with one, two or four lifting loops.

PP/HDPE Woven Sacks

ACE PACKAGING manufactures and exports one of the widest range of PP/HDPE Woven Sacks (PWS) and Small Bags that are available in polypropylene (PP) and high density polyethylene (HDPE) as woven sacks and small bags. Manufactured using the best available quality raw material, these PP/HDPE Woven bags are manufactured in different sizes and specifications as per the customers packaging requirements.

We offer 100% custom designed polypropylene woven bags as per the requirements and specifications of our customers. Our range of types of woven polypropylene sacks include regular uncoated PP/HDPE bags, laminated (coated) PP/HDPE bags or PP/HDPE bags with liners. In addition to this we can offer up to 4 color printing on each side. Our polypropylene woven fabric construction makes our PP/HDPE bags very strong, tear resistant, light weighted, breathable and most importantly extremely cost effective.

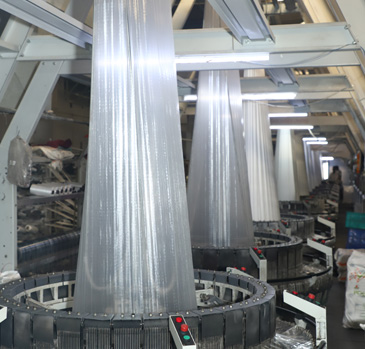

PP/HDPE Woven Fabrics

ACE PACKAGING manufactures one of the widest range of industrial grade clean Polypropylene (PP) and High density polyethylene (HDPE) Woven Fabric. PP/HDPE Woven Fabrics are used for manufacturing packaging bags which are available in different colors and dimensions as per customer requirements. PP/HDPE woven fabrics are comfortable, soft and crinkle free and can easily be loaded on any cutting and stitching machines.

ACE PACKAGING manufactures and exports PP/HDPE Tubular/Circular Fabric to very stringent quality controls which are implemented while making the circular woven PP fabric. Our customers receive world class quality PP/HDPE circular fabric with the right technical parameters, giving them the market edge for their final PP/HDPE product. By providing 100% customized PP/HDPE fabric including parameters such as size, GSM, color, mesh, UV and other parameters to required specifications, our customers are assured with the right product. PP Woven Circular fabric is also widely used for making PP Bale wraps, PP box bags, PP Courier bags and PP perforated bags.

LDPE Liner

LDPE Bags are used in various Industries such as: Automobile, Chemical, Pharmaceutical, Garments, Textile, etc for packing of products. These LDPE bags, LDPE plastic bags and LDPE rolls prevent the product From Dust/Rain and Transit Damage. LDPE Rolls & Bags are being made as per the needs of the company depending upon various specifications of the Product.

LDPE (low density polyethylene) and its cousin LLDPE (linear low-density polyethylene) are the workhorses of the poly bag industry. They are widely used for its clarity and inherent flexibility. We are one of the leading manufacturers of LD Liner Bag. We obligated to meet the quality standards as per the customer demand. We are one of the leading manufacturers of LDPE Liner Bag. We obligated to meet the quality standards as per the customer demand.

We are a renowned manufacturer and exporter of an excellent stock of LDPE Liners LDPE Form Fit Liner and LDPE Bag. Made of best quality low-density polyethylene, these liners are widely used for packaging various products such as chemicals and food products. We stringently test these liners on varied standard quality parameters such as strength and durability.

Features: These liners can withstand extreme temperatures, these are manufactured in compliance with FDA standards, Acclaimed among clients for their high tear resistance.